The data is in, and there’s no mistaking the results: to improve the efficiency of operations and address increasingly steep customer expectations, apparel retailers are investing heavily in material handling automation in 2023.

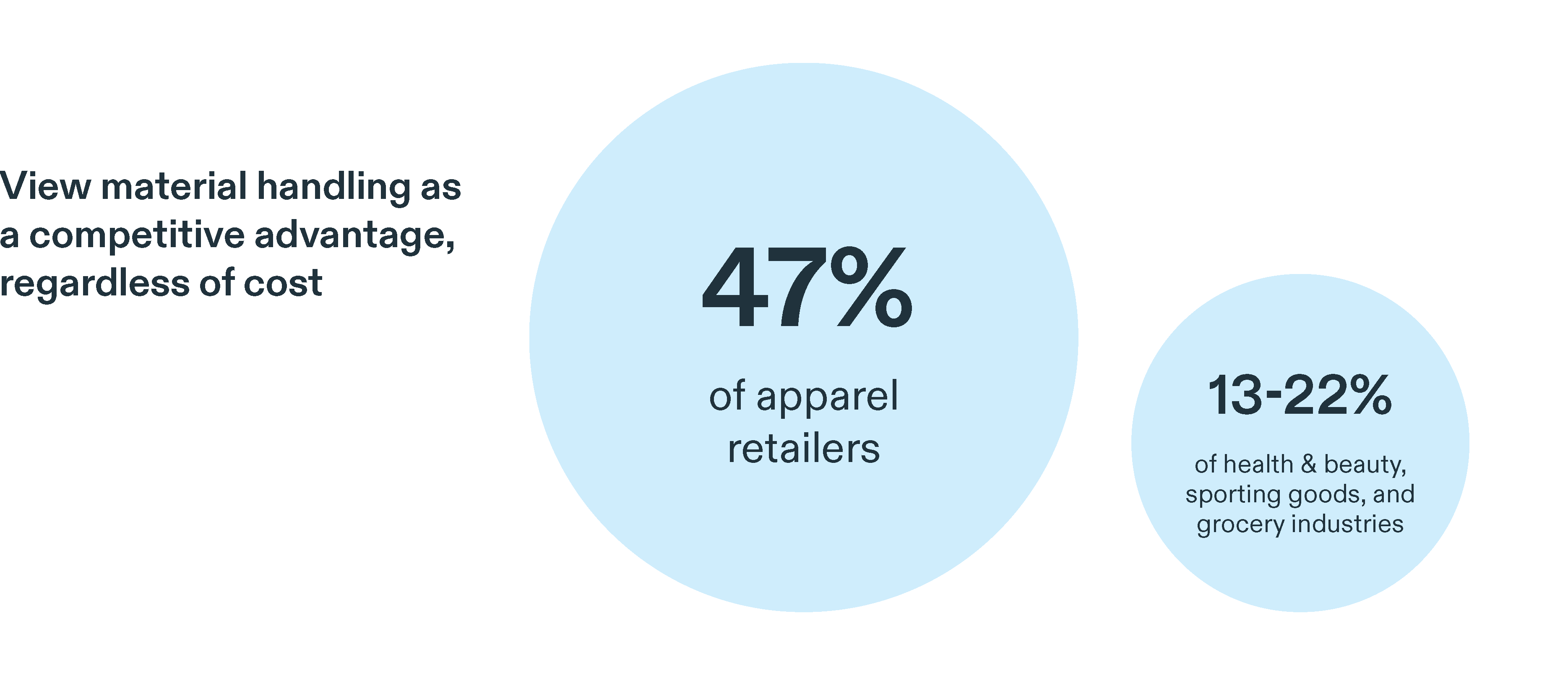

In a recent survey of 150 retail and logistics executives conducted by Covariant and Supply Chain Dive, apparel retailers stand out from all other verticals for their commitment to material handling. In fact, 47% of apparel retailers view material handling as a competitive advantage — no matter the costs involved. In comparison, only 13—22% of respondents in the health & beauty, sporting goods, and grocery industries saw material handling as a competitive advantage.

Additionally, 39% of apparel retailers view material handling as an advantage while balancing changes and improvements with cost efficiency. These numbers are between 15% and 30% for the industries mentioned above.

Automation technology is the differentiator apparel retailers will use to achieve and maintain this competitive advantage. Nearly half of the retailers in this vertical — 45% — say they plan to invest in increasing brownfield efficiency and automation in 2023, while 64% still plan to invest in greenfield facilities despite economic uncertainty.

Why are apparel retailers so strong on material handling automation?

The apparel industry faces unique operational requirements and high customer demands

SKU variability

Due to changing customer preferences, fashion trends, and seasonality, many apparel retailers manage inventory with a limited shelf life. This variability leads to frequent SKU turnover, which makes it difficult to predict inventory needs in advance.

As one academic review of demand forecasting in the apparel industry puts it, “In the fashion industry, products are usually characterized by long replenishment lead times, short selling seasons, and nearly unpredictable demand and therefore, inaccurate forecasts.”

Apparel retailers must balance these vacillating conditions and planning difficulties while avoiding shortages, surpluses, and bottlenecks to process SKUs efficiently as they change over.

This is one among several reasons why apparel retailers are turning to material handling innovation. Unlike previous attempts at automated piece picking, AI Robotics automation quickly and fluidly adapts to new SKUs so inventory can be processed quickly, even amid frequent changes.

High customer expectations

Half of the apparel retailers surveyed identify customer delivery expectations as a challenge in 2023. According to a McKinsey report, 90% of customers expect a two- to three-day delivery window, while 30% expect same-day delivery.

In addition to fast order turnaround, an easy returns process is also critical for apparel retailers. Customers often order multiple sizes, colors, and styles, planning to keep what works and send back the rest at little or no cost to themselves. In the face of labor shortages and an erratic economic environment, this level of service can be difficult to maintain — but customer expectations are unwavering.

Every step of the fulfillment process must be optimized along the way to meet these demands, including warehouse operations. Relying too heavily on manual labor creates operational vulnerabilities, as there are often labor gaps to fill due to high turnover and limited access to talent. AI Robotics automation removes vulnerability, ensuring operations always have reliable means to deliver the speedy turnaround customers now expect for their orders and returns.

Improving material handling

During the COVID-19 pandemic, consumers shifted their buying behavior rapidly toward e-commerce. For 53% of survey respondents, managing the continued growth of e-commerce rates is a top challenge in 2023 as they continue to navigate the pressures of delivering seamless omnichannel experiences. To keep up, efficient warehouse operations are critical — and for that, apparel retailers are highly motivated to explore new strategies for managing material handling and logistics.

Navigating dips and surges and a high dependency on human labor are also top challenges for apparel retailers. Ebbs and flows make it difficult to align inventory with demand and consistently staff correctly. AI Robotics automation helps operations quickly scale up or down, making it easier for apparel retailers to respond to real-time demand.

Apparel retailers investing in a broad range of robotic picking use cases

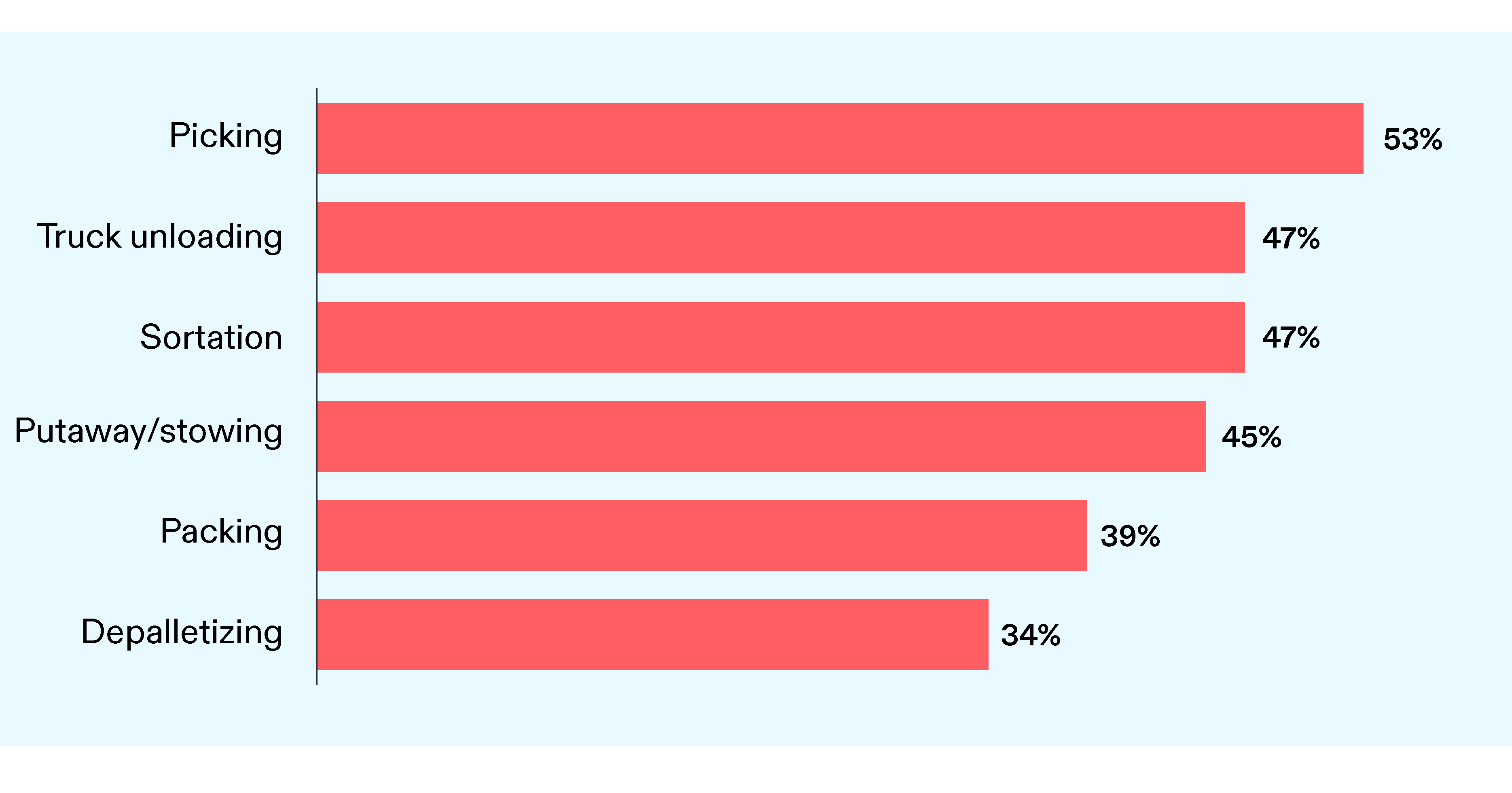

To improve material handling, apparel retailers are focused on investing in the following areas of robotic picking:

These investments rise to the top for good reason. Due to SKU variability and the level of picking precision needed in apparel retail, the manual tasks of picking, packing, kitting, and sorting have been historically difficult to automate. But modern deep-learning-based AI, such as the Covariant Brain — universal AI that empowers robots to see, think, and act — eliminates that barrier. Now, warehouses can automate the “hands” and “feet” to bring the efficiency of AI-powered automation to known bottlenecks.

Bringing robotic picking to truck unloading, depalletizing, and putaway/stowing will help apparel retailers efficiently clear space and prevent backups so inventory can be processed faster and more accurately.

Apparel retailers have big expectations for robotic picking investments

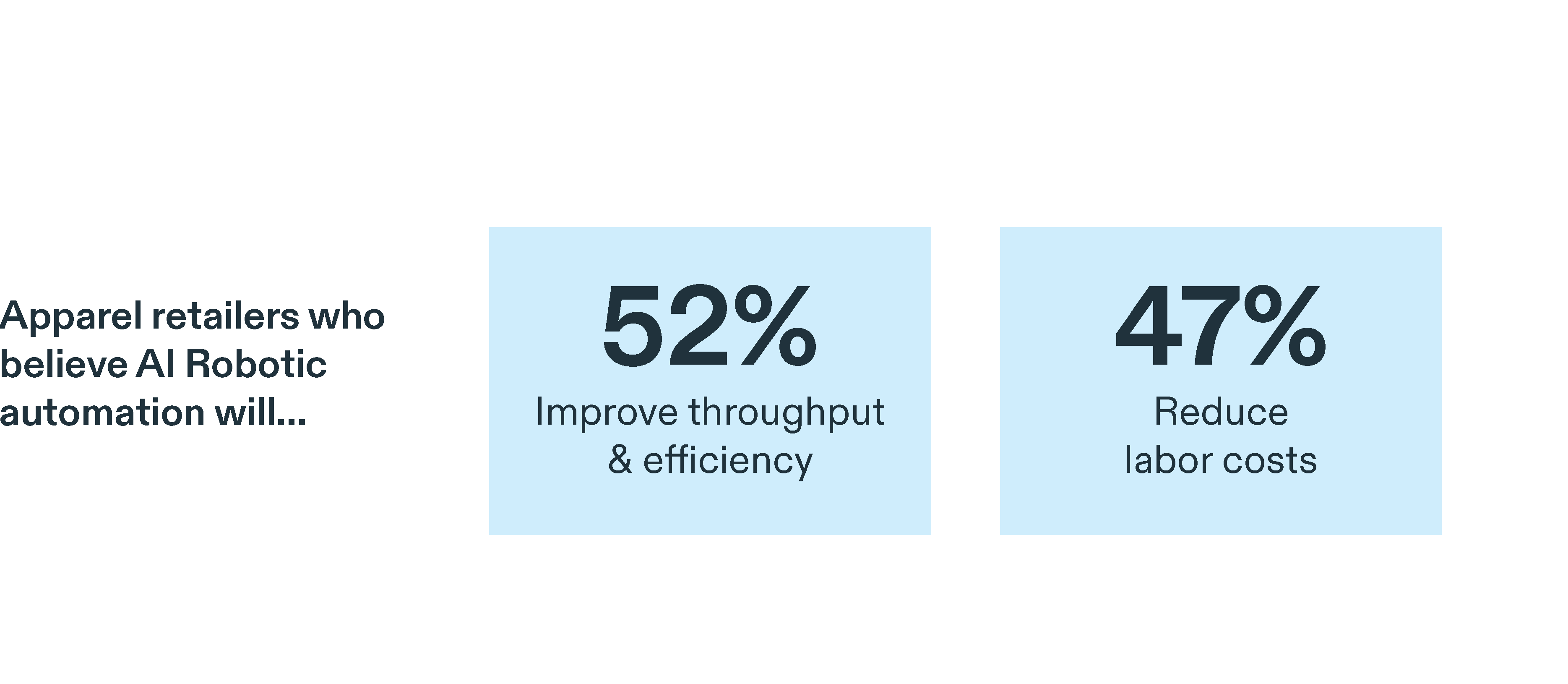

A majority of apparel retailers (52%) anticipate that AI Robotic automation will improve throughput and efficiency to keep up with competitors and customer demands while ensuring operational flexibility.

The same number believe that AI Robotics automation will help them prepare for changing business needs, from rapidly shifting use cases and adapting to new SKUs to staying ahead of competitors.

Finally, 47% plan to reduce labor costs as a result of robotic picking investments. This will create capital efficiency and allow apparel retailers to continue to invest in innovation that leads to gains in productivity.

Automation is a must-have for apparel retailers moving forward

Apparel retailers are on the hunt for solutions that will help them address increasingly high customer expectations and navigate complex fulfillment operations. Our results show they see those solutions in material handling automation. Those that decide to prioritize material handling investments in 2023 will see significant improvements to throughput, efficiency, and labor while gaining a competitive edge that so many in this vertical can’t wait to create.

To learn more about how retailers are investing in 2023, download the full report.

Cover photo credit: Photo by Korie Cull on Unsplash