About Capacity

Capacity, a forward-thinking third-party logistics firm with expertise in Health and Beauty products for brands like Merit Beauty and Alastin Skincare, was seeking new ways to improve their warehouse throughput. The combination of unpredictable spikes in demand with limited staff availability was decreasing the 3PL company’s efficiency. The operations team had experimented with a robotic automation solution for order sortation earlier that year but it had been unsuccessful.

Prior challenges at the Capacity warehouse

“After two years of testing a different robotic putwall, it became clear the station would never meet the benchmark metrics required for financial viability,” shared Thom Campbell, Chief Strategy Officer of Capacity. “The team was skeptical that these next-generation automation solutions were ready for the real world.”

After meeting Covariant at an industry event, the Capacity team was cautiously optimistic about trying another robotic order sortation solution. “We embrace innovation at Capacity and pride ourselves on being early adopters,” Campbell continued. “We were hesitant to try another robotics vendor but Covariant’s deep bench of AI talent described a robotics solution that was actually intelligent and could be autonomous in real life. We had to try it.”

Superior performance with untested SKUs

To begin the vendor assessment, the Capacity team mailed Covariant a variety of products to pick and place in a putwall. Health & beauty products tend to be small, irregularly shaped, and often encased in transparent plastic packaging. The combination of size, shape, and packaging is often a challenge for computer vision to accurately pick. The Covariant Brain leverages AI to specifically address these challenges and enable robots to successfully handle a virtually infinite variety of objects. Based on original research, the Covariant team followed a standardized unbiased assessment for demonstrating their technology’s value. [To download the assessment for free, visit here.]

“Watching the uncut recording of the Covariant robot successfully picking and placing brand-new items it had never encountered was when I started to get excited about the possibilities of AI-powered robotics and its superior learning abilities,” shared Campbell. “The market is getting noisier and it can be hard to tell what is just hype. The Covariant Brain is the real deal.”

After completing the initial test, Capacity also required Covariant to demonstrate the robot’s ability to scan SKUs accurately -- another important requirement of the putwall application. Covariant again demonstrated success with industry-leading accuracy.

Easy integration and installation

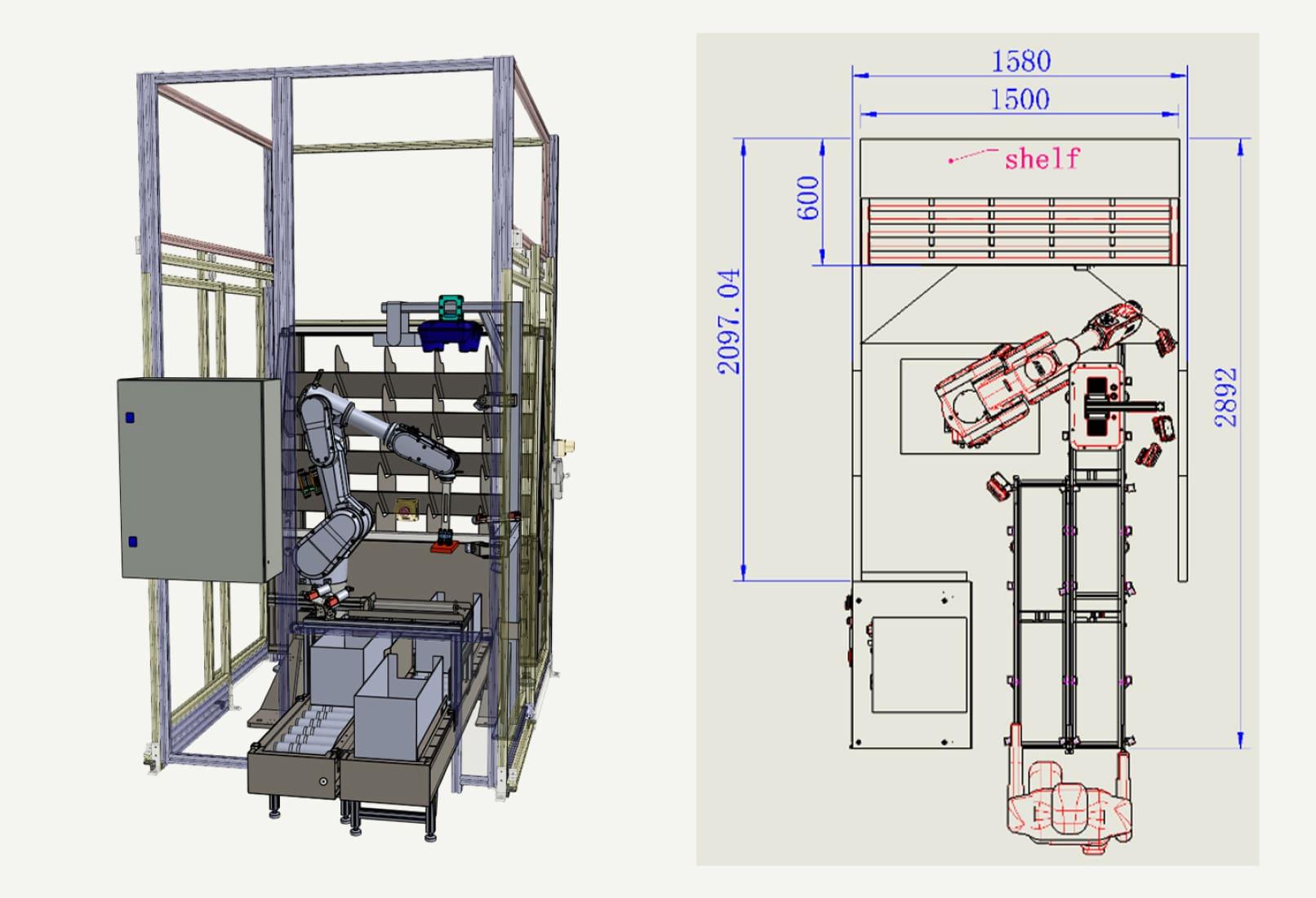

The Covariant team partnered with Capacity to integrate with the systems and processes without needing to overhaul the materials handling workflow and floorplan. The Covariant Robotic Putwall station (consisting of the Covariant Brain, robot arm, conveyors, scanners, and vision system) was customized to meet Capacity’s unique operational settings resulting in value on Day 1.

“Covariant’s solution team not only had the technical expertise but also a collaborative approach,” said Ed Shapiro, Director of Engineering at Capacity. “The collective mindset of our teams ensured a successful deployment and continuing success.”

Maximizing fulfillment throughput with a reliable robotic workforce

In June 2021, Capacity’s first Covariant Brain-powered Robotic Putwall went live in production. The team adopted the Covariant robot as one of its own – even nicknaming it Waldo. Soon after the successful integration and deployment of the first station, running at up to 515 picks per hour (PPH) with less than 0.1% of orders requiring human intervention, Capacity expanded its robot fleet to five Covariant Robotic Putwalls. The Capacity team has named the robotic additions: C-3PL, Maggie, PutWALL-E and Jarvis.

Leveraging Covariant's cutting-edge robotic technology, the Capacity warehouse is able to scale fulfillment operations for brands like Merit Beauty and Alastin Skincare, at a moment’s notice. When a celebrity-led beauty brand launches a new product at midnight on a Tuesday, the Capacity team is able to instantly meet that demand without having to scramble for additional staff. The same reliability and cost-effectiveness is achieved during the peak holiday season when the warehouse's productivity needs to perform at an all-time high.